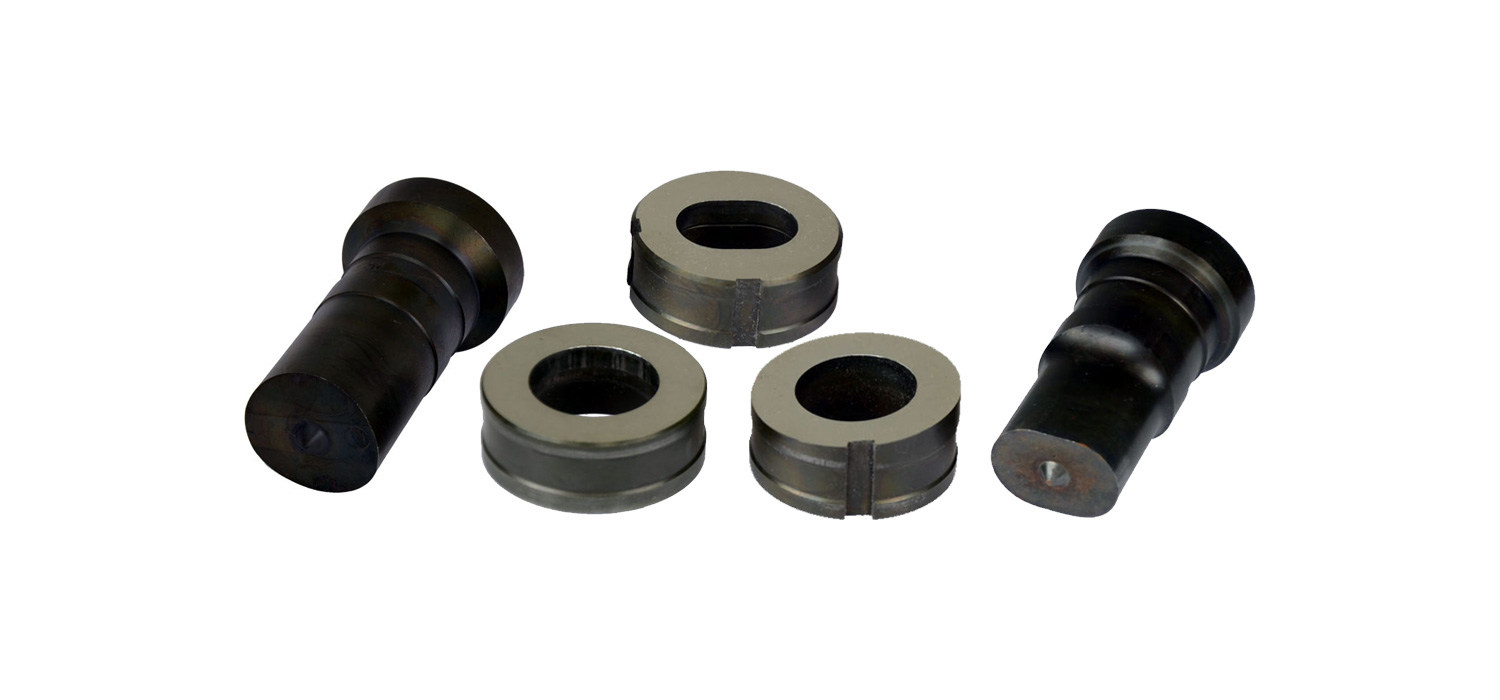

ROUND

| Round(mm) | Punch – Part No. | Die – Part No. | Taper Die – Part No. |

|---|---|---|---|

| Hydraulic Punchers Tools |  |

|

|

| 7 | STM-0507-20-18-00-0 | MTY-0507-40-18-00-0 | – |

| 8 | STM-0507-20-17-00-0 | MTY-0507-40-17-00-0 | – |

| 9 | STM-0507-20-16-00-0 | MTY-0507-40-16-00-0 | MTY-0507-50-16-00-0 |

| 10 | STM-0507-20-15-00-0 | MTY-0507-40-15-00-0 | MTY-0507-50-15-00-0 |

| 11 | STM-0507-20-14-00-0 | MTY-0507-40-14-00-0 | MTY-0507-50-14-00-0 |

| 12 | STM-0507-20-13-00-0 | MTY-0507-40-13-00-0 | MTY-0507-50-13-00-0 |

| 13 | STM-0507-20-12-00-0 | MTY-0507-40-12-00-0 | MTY-0507-50-12-00-0 |

| 14 | STM-0507-20-11-00-0 | MTY-0507-40-11-00-0 | MTY-0507-50-11-00-0 |

| 15 | STM-0507-20-10-00-0 | MTY-0507-40-10-00-0 | MTY-0507-50-10-00-0 |

| 16 | STM-0507-20-09-00-0 | MTY-0507-40-09-00-0 | MTY-0507-50-09-00-0 |

| 17 | STM-0507-20-08-00-0 | MTY-0507-40-08-00-0 | MTY-0507-50-08-00-0 |

| 18 | STM-0507-20-07-00-0 | MTY-0507-40-07-00-0 | MTY-0507-50-07-00-0 |

| 19 | STM-0507-20-06-00-0 | MTY-0507-40-06-00-0 | MTY-0507-50-06-00-0 |

| 20 | STM-0507-20-05-00-0 | MTY-0507-40-05-00-0 | MTY-0507-50-05-00-0 |

| 21 | STM-0507-20-04-00-0 | MTY-0507-40-04-00-0 | MTY-0507-50-04-00-0 |

| 22 | STM-0507-20-03-00-0 | MTY-0507-40-03-00-0 | MTY-0507-50-03-00-0 |

| 23 | STM-0507-20-02-00-0 | MTY-0507-40-02-00-0 | MTY-0507-50-02-00-0 |

| 24 | STM-0507-20-01-00-0 | MTY-0507-40-01-00-0 | MTY-0507-50-01-00-0 |

| 25 | STM-0507-20-00-00-0 | MTY-0507-40-00-00-0 | MTY-0507-50-00-00-0 |

| 26 | STM-0507-20-19-00-0 | MTY-0507-40-19-00-0 | MTY-0507-50-19-00-0 |

| 27 | STM-0507-20-20-00-0 | MTY-0507-40-20-00-0 | MTY-0507-50-20-00-0 |

OBLONG

| Oblong(mm) | Punch – Part No. | Die – Part No. |

|---|---|---|

| Hydraulic Punchers Tools |  |

|

| 16×8 | STM-0507-30-13-00-0 | MTY-0507-70-13-00-0 |

| 18×9 | STM-0507-30-12-00-0 | MTY-0507-70-12-00-0 |

| 18×11 | STM-0507-30-11-00-0 | MTY-0507-70-11-00-0 |

| 20×10 | STM-0507-30-10-00-0 | MTY-0507-70-10-00-0 |

| 20×12 | STM-0507-30-09-00-0 | MTY-0507-70-09-00-0 |

| 20×14 | STM-0507-30-08-00-0 | MTY-0507-70-08-00-0 |

| 20×11 | STM-0507-30-07-00-0 | MTY-0507-70-07-00-0 |

| 20×14 | STM-0507-30-06-00-0 | MTY-0507-70-06-00-0 |

| 20×12 | STM-0507-30-05-00-0 | MTY-0507-70-05-00-0 |

| 25×9 | STM-0507-30-04-00-0 | MTY-0507-70-04-00-0 |

| 25×12 | STM-0507-30-03-00-0 | MTY-0507-70-03-00-0 |

| 25×13 | STM-0507-30-02-00-0 | MTY-0507-70-02-00-0 |

| 25×14 | STM-0507-30-01-00-0 | MTY-0507-70-01-00-0 |

| 25×18 | STM-0507-30-00-00-0 | MTY-0507-70-00-00-0 |

Various hydraulic punch tools are available on request – in imperial metric sizes.

Punch Dia. V/S Maximum Plate Thickness

TUSKER 60

CIRCULAR HOLES using Circular Punches with Metric Sizes

| Dia. Ø |

Mild Steel Rm < 490 MPa |

Hard Steel Rm = 490-630 MPa |

Stainless Steel Rm = 630-750 MPa |

|---|---|---|---|

| (mm) | Maximum Plate Thickness in mm | ||

| 7 | 5.6 | 3.5 | 2.8 |

| 8 | 6.4 | 4.0 | 3.2 |

| 9 | 7.2 | 4.5 | 3.6 |

| 10 | 8.0 | 5.0 | 4.0 |

| 11 | 8.8 | 5.5 | 4.4 |

| 12 | 9.6 | 6.0 | 4.8 |

| 13 | 10.4 | 6.5 | 5.2 |

| 14 | 11.2 | 7.0 | 6.0 |

| 15 | 12.0 | 7.5 | 6.0 |

| 16 | 12.8 | 8.0 | 6.0 |

| 17 | 13.0 | 8.5 | 6.0 |

| 18 | 13.0 | 9.0 | 6.0 |

| 19 | 13.0 | 9.5 | 6.0 |

| 20 | 13.0 | 10.0 | 5.0 |

| 21 | 13.0 | 10.5 | 5.0 |

| 22 | 13.0 | 10.3 | 5.0 |

| 23 | 12.4 | 9.9 | 4.0 |

| 24 | 11.9 | 9.5 | 4.0 |

| 25 | 11.4 | 9.1 | 4.0 |

| 26 | 11.0 | 8.7 | 4.0 |

| 27 | 10.6 | 8.4 | 4.0 |

TUSKER 60

OBLONG HOLES using Oblong Punches with Metric Sizes

| L X W | Mild Steel L X W Rm < 490 MPa |

Hard Steel Rm = 490-630 MPa |

Stainless Steel Rm = 630-750 MPa |

|---|---|---|---|

| (mm) | Maximum Plate Thickness in mm | ||

| 16×8 | 6.4 | 4.0 | 3.2 |

| 18×9 | 7.2 | 4.5 | 3.6 |

| 18×11 | 8.8 | 5.5 | 4.4 |

| 20×10 | 8.0 | 5.0 | 4.0 |

| 20×12 | 9.6 | 6.0 | 4.8 |

| 20×14 | 11.2 | 7.0 | 6.0 |

| 22×11 | 8.8 | 5.5 | 4.4 |

| 22×14 | 11.2 | 7.0 | 6.0 |

| 22×12 | 9.6 | 6.0 | 4.8 |

| 25×9 | 7.2 | 4.5 | 3.6 |

| 25×12 | 9.6 | 6.0 | 4.8 |

| 25×13 | 10.4 | 6.5 | 5.2 |

| 25×14 | 11.2 | 7.0 | 6.0 |

| 25×18 | 13.0 | 9.0 | 6.0 |

TUSKER 110

CIRCULAR HOLES using Circular Punches with Metric Sizes

| Dia. Ø |

Mild Steel Rm < 490 MPa |

Hard Steel Rm = 490-630 MPa |

Stainless Steel Rm = 630-750 MPa |

|---|---|---|---|

| (mm) | Maximum Plate Thickness in mm | ||

| 7 | 5.6 | 3.5 | 2.8 |

| 8 | 6.4 | 4.0 | 3.2 |

| 9 | 7.2 | 4.5 | 3.6 |

| 10 | 8.0 | 5.0 | 4.0 |

| 11 | 8.8 | 5.5 | 4.4 |

| 12 | 9.6 | 6.0 | 4.8 |

| 13 | 10.4 | 6.5 | 5.2 |

| 14 | 11.2 | 7.0 | 6.0 |

| 15 | 12.0 | 7.5 | 6.0 |

| 16 | 12.8 | 8.0 | 6.0 |

| 17 | 13.6 | 8.5 | 6.0 |

| 18 | 14.4 | 9.0 | 6.0 |

| 19 | 15.2 | 9.5 | 6.0 |

| 20 | 16.0 | 10.0 | 6.0 |

| 21 | 16.0 | 10.5 | 6.0 |

| 22 | 16.0 | 11.0 | 6.0 |

| 23 | 16.0 | 11.5 | 6.0 |

| 24 | 16.0 | 12.0 | 6.0 |

| 25 | 16.0 | 12.5 | 6.0 |

| 26 | 15.1 | 12.0 | 6.0 |

| 27 | 14.5 | 11.5 | 6.0 |

TUSKER 110

OBLONG HOLES using Oblong Punches with Metric Sizes

| L X W | Mild Steel L X W Rm < 490 MPa |

Hard Steel Rm = 490-630 MPa |

Stainless Steel Rm = 630-750 MPa |

|---|---|---|---|

| (mm) | Maximum Plate Thickness in mm | ||

| 16×8 | 6.4 | 4.0 | 3.2 |

| 18×9 | 7.2 | 4.5 | 3.6 |

| 18×11 | 8.8 | 5.5 | 4.4 |

| 20×10 | 8.0 | 5.0 | 4.0 |

| 20×12 | 9.6 | 6.0 | 4.8 |

| 20×14 | 11.2 | 7.0 | 6.0 |

| 22×11 | 8.8 | 5.5 | 4.4 |

| 22×14 | 11.2 | 7.0 | 6.0 |

| 24×12 | 9.6 | 6.0 | 4.8 |

| 25×9 | 7.2 | 4.5 | 3.6 |

| 25×12 | 9.6 | 6.0 | 4.8 |

| 25×13 | 10.4 | 6.5 | 5.2 |

| 25×14 | 11.2 | 7.0 | 6.0 |

| 25×18 | 14.4 | 9.0 | 6.0 |